SLITTING

PRECISE CUTTING FOR ALUMINUM

AND STEEL COILS

American Douglas Metals (ADM) slitting services skillfully produce custom widths for your aluminum or steel coils. Our state-of-the-art metal service center provides precise slitting services to a wide variety of industries.

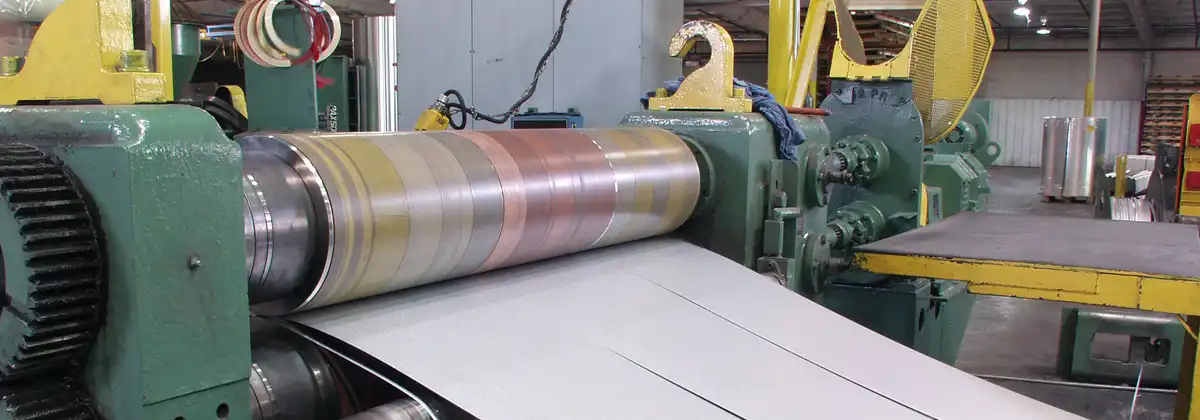

The Slitting process occurs when steel or aluminum coils are fed through a slitting machine and cut into narrow wedges with the use of slitting knives. Through slitting and the use of our full-service capabilities for your hot rolled or cold rolled steel, you are able to maintain a series of benefits to your final products.

Our metal slitting capabilities include:

- 40” Slitter

- 50” Slitter

- 52” Slitter

- 62” Slitter

- .0065” – .156” Gauge Range

(gauge ranges may differ depending on material) - .750” – 62” Slit Widths

- 46,000 lb. Maximum Coils

- Beveled Knives

- Inline Packaging Lines

- Looping Pits

- PVC Application/Removal

As a full-service metal center, our capabilities can help transform your aluminum and steel products to suit any project specifications.

REQUEST QUOTES OR

ADDITIONAL INFORMATION

To speak with an American Douglas Metals (ADM) representative regarding our available products or services, please fill out the form below and we will contact you as soon as possible.

HOW IT’S DONE

The slitting process itself is made up of three main components to achieve your finalized steel and aluminum products. With the use of slitter rewinders, your products will meet your high criteria every time.

The slitting process itself is made up of three main components to achieve your finalized steel and aluminum products. With the use of slitter rewinders, your products will meet your high criteria every time.

It first begins with the coil steel material or rolls of material needed after it has endured the hot rolled or cold rolled process. It is placed in a slitting machine, a slitter rewinder, to perform shearing to create more narrow rolls.

The metal material is placed in an uncoiler, an area of the machine unwraps the material, and it is then moved through a set of shears to begin the slitting process. These cutting shears are set according to the desired custom width provided by the design’s requirements.

The thickness of the material also depends on the machine being used.

The cut steel materials, or strands, are then measured by our team of professionals for quality assurance. After it is checked and approved, the material is then placed through a set of discs called separators to guide the slitted material to the recoiler.

The aluminum or steel material is then rolled back into a coil and packaged so it can be ready for shipping to our respective clients. The slit coil can also endure different sets of finishes, depending on the client’s manufacturing requests. Adding a corrosion-resistant finish is one of the best choices to make in order to maintain a durable and long-lasting material.

Your Products

This process is used regularly in the manufacturing industry to create necessary products we use every day such as:

- HVAC Ducts

- Lighting Fixtures

- Architectural Trims

- Roof Drain Pipes

Our steel and aluminum products are used in almost every industry that requires high-quality, high-strength, metal materials of any size and shape in order to achieve project goals. We have created finalized products that have been used in various industrial fields such as construction, manufacturing, aerospace, and so on.

Thanks to our precision-based equipment, no job is too complicated. We are up for the challenge when it comes to orders with extensive requirements in order to keep our clients and their consumers happy.

Why Utilize Steel Slitting

American Douglas Metals is future-proofing its industry standards through the use of sustainable practices. Sustainability is an important growing aspect in the manufacturing and production world as it helps us maintain our environment and community standards. If a company were to request any custom made slitting to be done, they are:

- Reducing scrap metal

- Reducing labor costs

- Creating a consistent end product

- Streamlined material flow

Through slitting and use of our other full-service capabilities, we can utilize our stock to meet your needs while being mindful of industrial waste.

Your Trusted Material Provider

American Douglas Metals (ADM) slitting services skillfully produce custom widths for your aluminum and steel coils and material. As a trusted metal service center, we provide precise slitting service to a wide variety of industries and production needs.

Learn More Of Our Other Steel and Aluminum Services:

SLITTING

Precise cutting to create custom-width coils.

CUT-TO-LENGTH

Converting flat-rolled coils into custom sized sheets.

BLANKING

Producing smaller sheets via CTL and/or shearing.

EMBOSSING

Pattern pressing for aluminum and steel

coiled metals

SHEARING

Reworking larger sheets into smaller sheets.

CNC MACHINING CENTER

State of the art, custom aluminum extrusion fabrication facility.