Precision aluminum extrusions for medical equipment have become indispensable in healthcare settings where alignment accuracy directly impacts device performance and patient outcomes. Aluminum is approximately one-third the weight of steel, making it an ideal material for medical applications that require both structural integrity and portability. This lightweight yet durable metal offers the perfect combination of strength and versatility for critical healthcare equipment.

Furthermore, aluminum extrusions provide manufacturers with almost limitless geometric possibilities, enabling innovative solutions that address specific medical device alignment challenges. The material’s high strength-to-weight ratio perfectly suits the needs of medical devices, particularly those requiring precise calibration and consistent performance. Common applications include hospital beds, IV poles, wheelchair frames, imaging equipment, and hospital carts, all of which benefit from aluminum’s inherent properties.

Additionally, aluminum is more affordable than both stainless steel and titanium, consequently making it an economically advantageous choice for medical device manufacturers concerned with both quality and cost-efficiency. Its corrosion resistance, durability, and flexibility ensure that medical equipment maintains structural integrity in demanding healthcare environments. This article explores how precision aluminum extrusions solve alignment challenges in medical devices and why partnering with the right aluminum extrusions supplier is essential for medical OEMs seeking to optimize performance and patient safety.

Key Takeaways

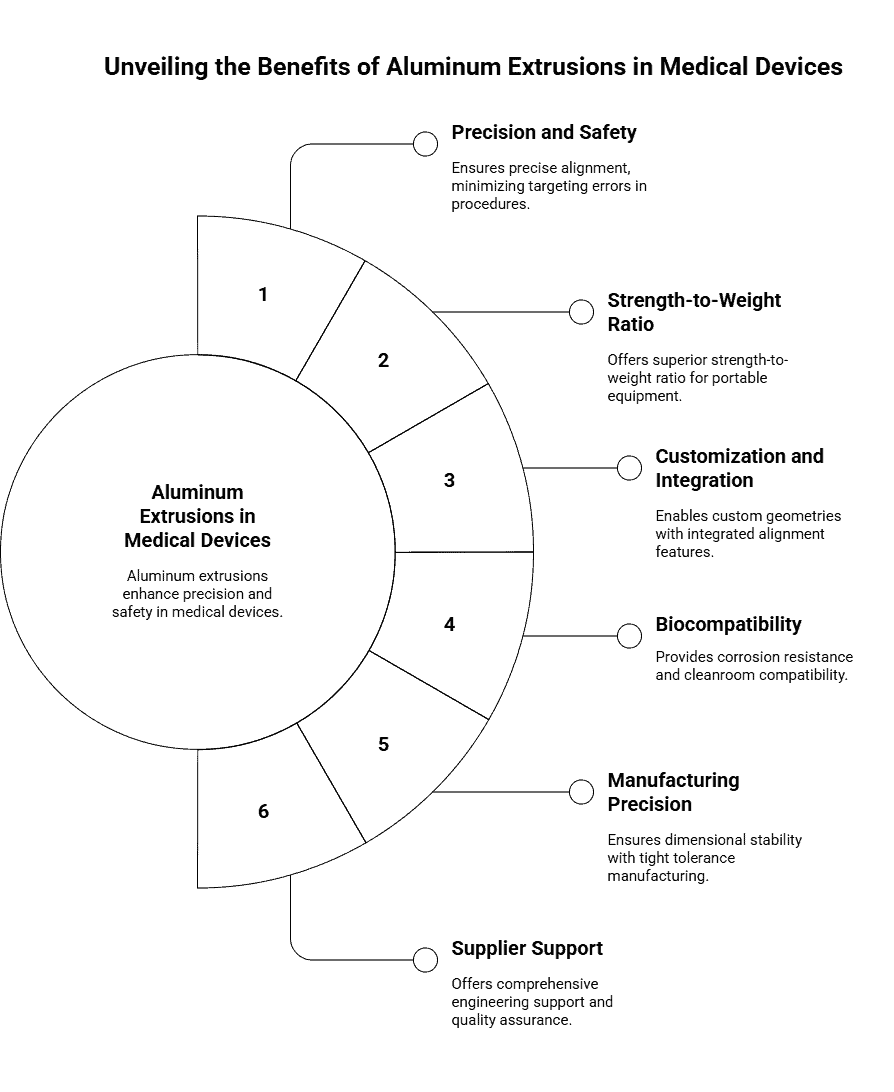

Medical device alignment precision is critical for patient safety, with even minimal frame deformation potentially increasing targeting errors from 0.71mm to 2.12mm in medical procedures.

- Aluminum extrusions offer superior strength-to-weight ratio, being three times lighter than steel while maintaining structural integrity for portable medical equipment.

- Precision aluminum extrusions enable custom profile geometries with integrated alignment features, reducing assembly time and eliminating weak points found in traditional joints.

- Biocompatible aluminum alloys (6061, 6063, 3003) provide corrosion resistance and cleanroom compatibility essential for sterile medical environments.

- Tight tolerance manufacturing (±0.002-0.005 inches) ensures dimensional stability throughout device lifecycle, reducing calibration frequency and regulatory compliance risks.

- Partnering with experienced suppliers like ADM provides comprehensive engineering support and quality assurance protocols critical for medical-grade applications.

The combination of material properties, manufacturing precision, and expert support makes aluminum extrusions an optimal solution for medical device manufacturers prioritizing alignment accuracy and patient safety.

Why Alignment Precision Matters in Medical Devices

Medical device alignment precision directly affects patient outcomes and healthcare quality. In the medical field, even the slightest deviation in equipment performance can lead to incorrect diagnoses or ineffective treatments. This precision begins with the structural integrity of the device frame itself, where accuracy requirements are often measured in fractions of a millimeter.

Device Calibration Errors from Frame Deformation

Frame deformation represents a significant source of error in medical equipment. Studies have shown that distortion can occur even at minimal levels of torque, with mechanical deformation during stereotactic procedures increasing targeting error from 0.71 mm (undistorted) to 2.12 mm with increased frame distortion. Moreover, when frame components are subjected to uneven pressure, the heterogeneity between opposing pairs of fixation points significantly raises the amount of frame distortion.

The implications of such deformation extend beyond simple mechanical issues. In radiotherapy imaging systems, calibration errors caused by frame deformation directly affect the accuracy of equipment alignment and spatial coordinates beyond the image center. Similarly, in endoscopic procedures, the mean absolute error in dynamic registration accuracy can reach 6.03 ± 0.96 mm when target tissues deform, potentially compromising procedural safety margins.

Regulatory Compliance Risks Due to Misalignment

Misalignment in medical devices creates significant regulatory compliance concerns. Regular calibration is essential for meeting stringent regulations from authorities like the FDA and ISO. When devices fall out of alignment due to frame issues:

- Healthcare facilities risk non-compliance with regulatory standards

- Service interruptions may occur during unplanned recalibration

- Potential legal issues can arise from equipment-related errors

The calibration process involves adjusting and verifying medical devices to ensure measurements align with established standards. However, this process becomes increasingly difficult when the underlying frame structure lacks stability. Indeed, precision-manufactured frames are fundamental to maintaining calibration over time.

The correlation between frame stability and calibration accuracy makes structural materials a critical consideration. Aluminum extrusions with tight tolerances provide the dimensional stability needed to maintain alignment throughout a device’s operational lifecycle, thereby reducing calibration frequency and supporting regulatory compliance while enhancing patient safety.

Material Advantages of Aluminum in Medical Applications

Aluminum stands out as an exceptional material for medical applications primarily because of its unique combination of physical and chemical properties. The metal delivers critical performance characteristics that address the specific demands of medical environments where precision and reliability are paramount.

High Strength-to-Weight Ratio for Portable Equipment

Aluminum is approximately three times lighter than steel, yet maintains remarkable structural integrity. This exceptional strength-to-weight ratio makes it ideal for portable medical equipment where every ounce matters. For healthcare professionals who use equipment repeatedly throughout their shifts, aluminum-framed devices reduce fatigue and improve maneuverability. This balance of strength and lightness specifically benefits:

- Mobile diagnostic equipment

- Patient transfer devices

- Adjustable examination tables

- Portable respiratory support systems

The lightweight nature of aluminum notably enhances device safety and efficiency, allowing for equipment designs that remain sturdy yet manageable even in emergency situations.

Corrosion Resistance in Sterile Environments

Medical settings present uniquely challenging conditions for materials, including exposure to bodily fluids, disinfectants, and harsh cleaning agents. Aluminum naturally forms a protective oxide layer that provides inherent resistance to corrosion, making it suitable for equipment that undergoes frequent sterilization. This resistance persists even when the material becomes nicked or scratched, thus ensuring long-term reliability in demanding healthcare environments.

Biocompatibility of 6061 and 6063 Aluminum Alloys

The medical industry typically utilizes three aluminum alloys that have passed biocompatibility testing: 6061, 6063, and 3003. These alloys are not only strong and corrosion-resistant but also non-toxic and safe for direct or indirect patient contact. The 6000 series alloys, especially 6061 and 6063, are highly favored for medical devices because of their strength, versatility, and excellent formability.

For enhanced biocompatibility, these alloys can be treated with anodization or chemical conversion coating (chem film). These surface treatments create stable, inert barriers that effectively seal the material, preventing any potentially harmful interaction with biological systems. Through such treatments, aluminum extrusions for medical equipment maintain both structural integrity and patient safety throughout their operational lifecycle.

Design and Manufacturing Benefits of Precision Extrusions

The advancement of precision extrusion technology enables remarkable engineering solutions for medical device manufacturers. With tolerances measured in ten-thousandths of an inch, these manufacturing techniques directly address critical alignment requirements.

Custom Profile Geometry for Alignment Control

Modern extrusion technology has progressed far beyond basic tubular components to create sophisticated profiles with integrated stops, bumps, and varying thicknesses in a single design. This capability allows engineers to develop custom geometries that provide inherent alignment control. Aluminum’s unparalleled design flexibility permits creation of intricate shapes necessary for specialized medical devices such as stethoscopes, trocars, and surgical tools. Unlike traditional manufacturing methods, precision extrusion delivers almost limitless geometric possibilities, effectively eliminating weak points commonly found at joints.

Reduced Assembly Time with Integrated Features

A major advantage of custom aluminum extrusions is the ability to produce a single profile that eliminates joining costs. This approach substantially reduces assembly time through:

- Shorter production lead times—tooling can often be completed within two weeks

- Lower tooling costs compared to stamping or injection molding

- Integrated functional elements that would otherwise require multiple components

Surface Finishing Options for Cleanroom Compatibility

For medical environments requiring sterile conditions, cleanroom aluminum profiles offer specialized surface treatments. These profiles feature rounded edges and smooth surfaces that prevent contaminant buildup. The aluminum can be anodized, creating a protective layer that eliminates oxidation possibilities. Available finishing options include mechanically polished surfaces for AMC and particulate control, electropolished treatments for smoothness and luster, or conductive powder coatings that provide electrostatic discharge protection. These surface treatments enhance both cleanliness compliance and functional performance in critical healthcare applications.

Partnering with ADM for Medical-Grade Aluminum Extrusions

American Douglas Metals (ADM) has established itself as a premier resource for medical device manufacturers since 1976, offering customized aluminum extrusion solutions that address critical alignment challenges in healthcare equipment.

ADM as a Trusted Aluminum Extrusions Supplier

ADM excels in producing custom aluminum extrusions according to precise specifications—whether raw, semi-finished, or completed profiles. The company primarily serves diverse industries requiring exceptional precision, making it ideally suited for medical device manufacturing where tolerances directly impact patient safety. Their expertise with 6000 Series aluminum, which contains added manganese and silicon for improved strength through solution heat-treatment, provides medical OEMs with materials specifically engineered for healthcare applications.

Tight Tolerance Extrusions Backed by QA Protocols

For medical device manufacturers, precision remains absolutely critical. ADM’s production capabilities ensure each extrusion meets strict dimensional requirements essential for proper device function. Their state-of-the-art facilities achieve tolerances as tight as ±.005 inches—in certain applications even reaching ±.002 inches. This level of precision guarantees that aluminum components fit perfectly within medical devices, subsequently enhancing both performance and reliability throughout the product lifecycle.

Consultative Engineering Support for OEM Projects

Beyond manufacturing, ADM offers comprehensive engineering support that streamlines the entire metalworking process. Their service center functions as an all-in-one shop—providing drilling, tapping, notching, milling, and cutting services for all extrusion projects regardless of specifications. This integrated approach eliminates the need for multiple vendors, ultimately reducing lead times and simplifying supply chain management for medical OEMs.

Contact ADM today to review your extrusion specifications and see how our tight-tolerance aluminum solutions can support your medical equipment builds.

Conclusion

Precision aluminum extrusions undoubtedly represent a critical advancement for medical device manufacturers facing alignment challenges. Throughout a device’s lifecycle, the dimensional stability provided by high-quality aluminum profiles ensures consistent performance while significantly reducing calibration frequency and associated downtime. Medical OEMs consequently benefit from reduced regulatory compliance risks and enhanced patient safety when utilizing properly engineered aluminum components.

The unique combination of strength-to-weight ratio, corrosion resistance, and biocompatibility makes aluminum alloys particularly well-suited for healthcare environments. Additionally, the design flexibility of precision extrusions allows manufacturers to create custom profiles with integrated alignment features, therefore eliminating weak points and streamlining assembly processes. These benefits translate directly to operational efficiency and improved device performance.

When selecting materials for medical equipment, the advantages of aluminum extend beyond mechanical properties to include economic considerations as well. The material’s affordability compared to alternatives like stainless steel and titanium, coupled with its exceptional durability, makes it a cost-effective choice for long-term device reliability.

For medical device manufacturers seeking to optimize alignment precision and overall equipment performance, partnering with an experienced aluminum extrusions supplier becomes essential. Contact ADM today to review your extrusion specifications and see how our tight-tolerance aluminum solutions can support your medical equipment builds. After all, precision in medical device manufacturing starts with the fundamental materials and expertise that ensure alignment accuracy throughout the entire product lifecycle.

FAQs

Q1. Why is alignment precision important in medical devices?

Alignment precision is crucial in medical devices because even slight deviations can lead to incorrect diagnoses or ineffective treatments. Precise alignment ensures accurate calibration, regulatory compliance, and ultimately, patient safety.

Q2. What are the advantages of using aluminum in medical equipment?

Aluminum offers a high strength-to-weight ratio, making it ideal for portable medical equipment. It’s also corrosion-resistant, biocompatible, and more affordable than alternatives like stainless steel or titanium.

Q3. How do precision aluminum extrusions help with medical device alignment?

Precision aluminum extrusions allow for custom profile geometries with integrated alignment features, reducing assembly time and eliminating weak points. They provide dimensional stability throughout a device’s lifecycle, ensuring consistent performance and reducing calibration frequency.

Q4. What surface finishing options are available for aluminum extrusions in medical applications?

Surface finishing options for aluminum extrusions in medical applications include anodization, mechanical polishing, electropolishing, and conductive powder coatings. These treatments enhance cleanroom compatibility, prevent contaminant buildup, and provide protection against oxidation.

Q5. How tight are the tolerances for aluminum extrusions used in medical devices?

Aluminum extrusions for medical devices can achieve tolerances as tight as ±0.005 inches, with some applications reaching ±0.002 inches. This level of precision ensures that components fit perfectly within medical devices, enhancing both performance and reliability.