As a cornerstone in various manufacturing sectors, the global aluminum extrusion market has been witnessing a significant upswing. The market overview examines an industry projected to grow from $90 billion in 2022 to $170 billion by 2030. The industry is expected to experience a yearly growth rate of 8.00%.

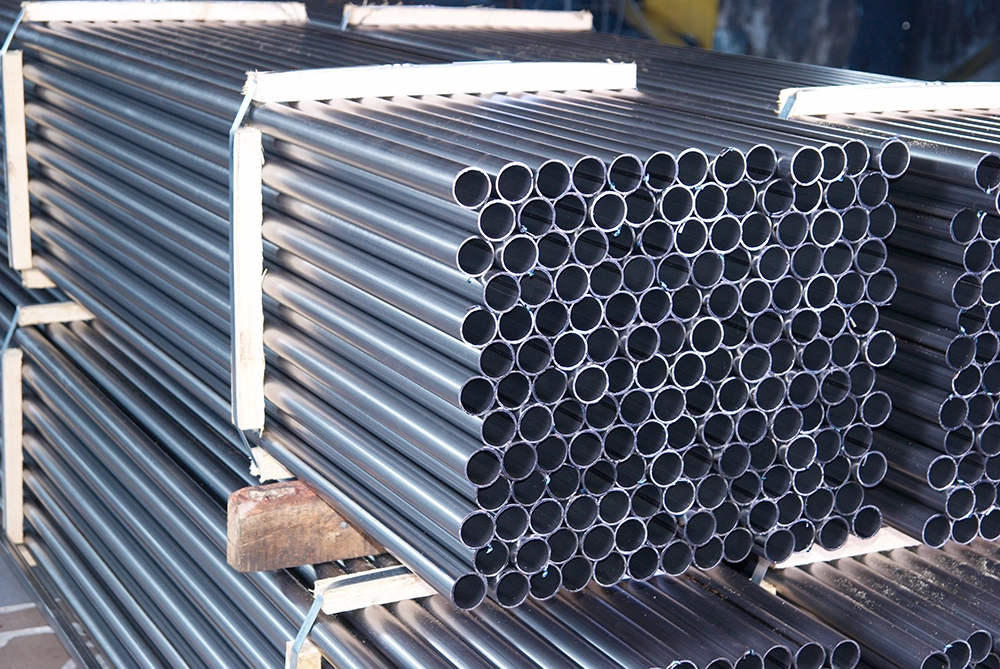

The increasing need for aluminum extrusion is driving its growth. It is used in various industries like construction and automotive because it is strong and lightweight. This trend reflects a broader market movement towards materials that offer both durability and efficiency.

The market is characterized by a diverse array of players, ranging from established giants to emerging innovators, all contributing to the dynamic landscape of the aluminum extrusion market. These market players are continuously adapting to evolving demands, employing advanced manufacturing techniques to cater to the growing need for high-quality aluminum extrusions.

This market overview will further explore how the increasing demand for aluminum extrusion, along with the strategic moves of key market players, is shaping the future of manufacturing sectors globally.

By examining the market’s current trajectory, we gain insights into how aluminum extrusion is becoming an indispensable material in an array of industries, underpinning new trends and driving technological advancements.

Aluminum Extrusion Explained

At its core, aluminum extrusion is a manufacturing process designed to create objects with a fixed cross-sectional profile. This involves forcing molten aluminum through a die, a shaped opening that gives the resulting extruded material its specific shape.

The process typically involves heating aluminum billets to a high temperature and then pushing or pulling them through the die using a hydraulic press or ram. This process is highly versatile and can produce complex shapes with a high degree of accuracy and consistency.

Market Segmentation

The global aluminum extrusion market can be segmented based on product type, alloy type, and end-use industry.

Product Types

The product type segment includes mill-finished, anodized, and powder-coated aluminum extrusions. Mill-finished products are aluminum profiles that have been extruded but not treated or finished. They were the biggest segment in 2022.

Alloy Types

In terms of alloy type, the market comprises the 1000, 2000, 3000, 5000, 6000, and 7000 series aluminum alloys. The 6000 series is widely used and has the most market share due to its strong, flexible, and corrosion-resistant properties.

End-Use Industries

The end-use industry segment includes building and construction, transportation, machinery and equipment, consumer durables, electrical, and others. The building and construction segment, due to the increased demand for lightweight and high-strength materials, has emerged as the dominant player.

Regional Analysis

Regional Analysis

On a regional scale, the market extends to North America, Europe, Asia-Pacific, and the Middle East and Africa. The Asia-Pacific region, thanks to its established automotive industry and rapid urbanization, currently dominates the global market.

Key Trends Shaping the Aluminum Extrusion Market

Sustainable Construction Practices: The aluminum extrusion market is increasingly influenced by the global shift towards sustainable construction. Aluminum extrusions, known for their lightweight yet strong characteristics, are becoming integral to architectural designs that focus on energy efficiency and aesthetic appeal. Aluminum’s recyclability is important in eco-friendly buildings, helping to meet environmental standards.

Technological Innovations: Technological advancements are a significant trend in the aluminum extrusion market. Innovations in extrusion techniques, such as precision extrusion, allow for more complex and intricate designs. These advancements are not only improving the quality and range of aluminum extruded products but are also driving efficiency and cost-effectiveness in production processes.

Automotive Industry’s Lightweight Revolution: In the automotive sector, there’s a growing trend of using aluminum extrusions for lightweight vehicle components. This change is part of a larger plan.

The plan aims to improve fuel use and reduce carbon emissions. These goals align with worldwide environmental targets. The aluminum extrusion market is playing a pivotal role in this automotive industry transformation by providing materials that combine strength with lightness.

Primary Drivers of the Aluminum Extrusion Market Growth

Demand in Diverse Industries: One of the primary drivers of the aluminum extrusion market is the material’s versatility and its demand across various industries. Aluminum extrusions are essential in construction, automotive, aerospace, electronics, and consumer goods due to their lightweight nature, corrosion resistance, and malleability. Each industry’s unique requirements, such as the need for robust yet lightweight materials in aerospace or durable and aesthetic components in construction, fuel the market’s growth.

Demand in Diverse Industries: One of the primary drivers of the aluminum extrusion market is the material’s versatility and its demand across various industries. Aluminum extrusions are essential in construction, automotive, aerospace, electronics, and consumer goods due to their lightweight nature, corrosion resistance, and malleability. Each industry’s unique requirements, such as the need for robust yet lightweight materials in aerospace or durable and aesthetic components in construction, fuel the market’s growth.

Global Urbanization and Infrastructure Expansion: The rapid pace of urbanization and the subsequent expansion of infrastructure projects worldwide significantly drive the aluminum extrusion market. As cities grow and update, the need for aluminum products in construction, transportation, and urban projects rises, boosting the market.

Focus on Energy Efficiency and Sustainability: The growing emphasis on energy efficiency and sustainability in manufacturing and construction is propelling the aluminum extrusion market forward. Aluminum is a popular material for eco-friendly practices due to its recyclability and energy-efficient design, leading to high demand.

Competitive Landscape

The competitive landscape of the market is characterized by the presence of several key players, including UAJC Corporation, Constellium, Norsk Hydro ASA, China Zhongwang Holding Limited, Kaiser Aluminum, Extrudex Aluminum, Gulf Extrusions Co., Novelis, AMG Advanced Metallurgical Group, and Hindalco Industries Ltd, among others.

Conclusion

The Aluminum Extrusion Market is growing globally. This growth is driven by sustainable architecture, demand in the automotive and transportation sectors, and advancements in manufacturing processes.

As a major player in the metals industry, American Douglas Metals (ADM) exemplifies a blend of experience, quality, and commitment to both industry and community.

With its wide range of product and service offerings, ADM stands as a reliable and proficient partner in providing tailored marketing solutions that generate value for clients in various industries.

Citations:

- https://www.grandviewresearch.com/industry-analysis/aluminum-extrusion-market

- https://www.linkedin.com/pulse/aluminum-extrusion-market-size-2023/

- https://www.linkedin.com/pulse/global-aluminum-extrusion-market-size-unleashing/

- https://www.marketresearchfuture.com/reports/aluminum-extrusion-market-10688

- https://www.imarcgroup.com/aluminium-extrusion-market