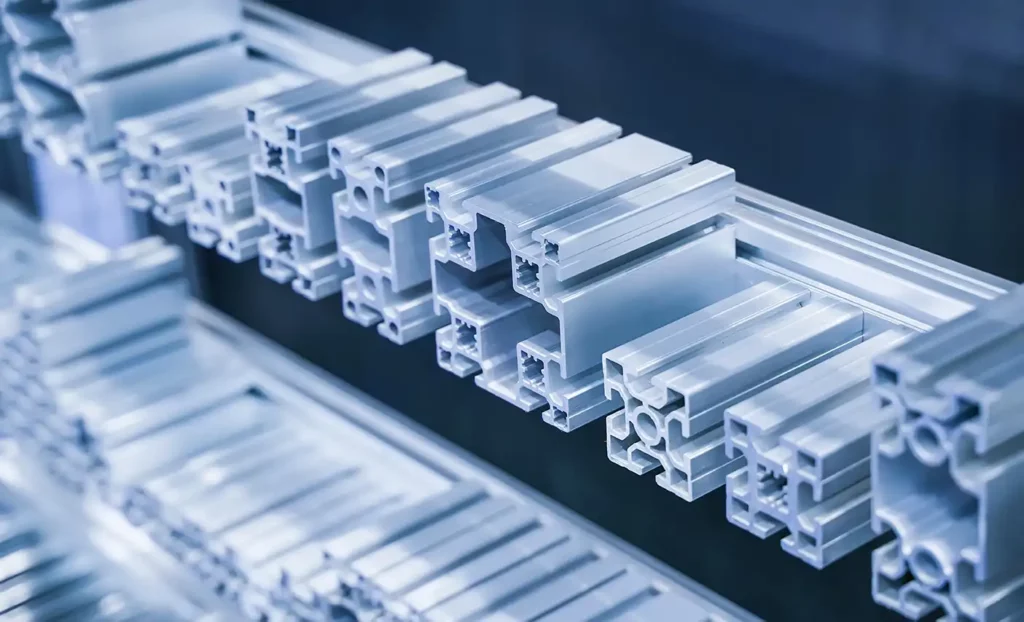

Extruded Aluminum Shapes: Versatile Solutions for Various Industries

At American Douglas Metals (ADM), we are proud to offer a wide range of high-quality extruded aluminum shapes. With over 43 years of experience in the industry, we have become a trusted leader in providing customized metal solutions to various industries. From construction and aerospace to automotive and electronics, our extruded aluminum shapes offer versatility, strength, and cost-effectiveness. Let’s explore how different industries utilize these shapes for their unique applications.

Construction Industry: Enhancing Durability and Aesthetics

In the construction industry, extruded aluminum shapes are extensively used for their durability, versatility, and aesthetic appeal. The lightweight nature of aluminum makes it an ideal choice for applications such as shed and trailer construction, where lightweight yet sturdy materials are crucial. Aluminum guide rails and paneling are commonly employed in these projects.

In the construction industry, extruded aluminum shapes are extensively used for their durability, versatility, and aesthetic appeal. The lightweight nature of aluminum makes it an ideal choice for applications such as shed and trailer construction, where lightweight yet sturdy materials are crucial. Aluminum guide rails and paneling are commonly employed in these projects.

Furthermore, aluminum extrusions find their way into denser structures, serving as essential elements in architectural designs. Balustrades, railings, and building façades benefit from the strength and corrosion resistance offered by aluminum extrusions. Canopies, which require lightweight yet robust structures, are also frequently constructed using our extruded aluminum shapes.

In interior construction, extruded aluminum plays a vital role. Elevator shafts, stairwells, and lighting fixtures often incorporate aluminum extrusions for their structural integrity and attractive appearance. The versatility of aluminum allows for various design possibilities, enabling architects and designers to create unique and functional spaces.

Aerospace Industry: Lightweight Strength for High-Flying Applications

The aerospace industry relies heavily on extruded aluminum shapes for their exceptional strength-to-weight ratio. Aluminum extrusions are extensively used in aircraft construction, from fuselage and wing skins to stringers and spars. The lightweight nature of aluminum helps reduce the overall weight of aircraft, leading to improved fuel efficiency and performance.

The aerospace industry relies heavily on extruded aluminum shapes for their exceptional strength-to-weight ratio. Aluminum extrusions are extensively used in aircraft construction, from fuselage and wing skins to stringers and spars. The lightweight nature of aluminum helps reduce the overall weight of aircraft, leading to improved fuel efficiency and performance.

The corrosion resistance of aluminum is another crucial factor in aerospace applications. Aluminum extrusions withstand the harsh conditions of flight, including exposure to moisture and temperature fluctuations. This resistance ensures the longevity and reliability of aerospace components, contributing to the safety and efficiency of aircraft.

Moreover, extruded aluminum shapes are employed in the production of flight control surfaces such as ailerons, elevators, and rudders. Landing gear struts and other structural components also benefit from the strength and durability of aluminum extrusions. The aerospace industry relies on the precision and quality of extruded aluminum shapes to ensure the safety and performance of aircraft.

Automotive Industry: Lightweight Solutions for Enhanced Performance

In the automotive industry, the demand for lightweight yet durable materials is constantly growing. Aluminum extrusions offer the perfect solution, providing the necessary strength while significantly reducing weight. By using our extruded aluminum shapes, automotive manufacturers can design vehicles that are more fuel-efficient, responsive, and environmentally friendly.

Aluminum extrusions find applications in various automotive components, including panels, engine blocks, roof rails, and transmission housings. The high strength-to-weight ratio of aluminum allows for the production of structural elements that are lighter than their steel counterparts, without compromising on strength and safety.

Additionally, the corrosion resistance of aluminum ensures the longevity of automotive components, even in harsh environmental conditions. Aluminum extrusions are also used in the manufacturing of battery boxes for electric vehicles, contributing to the efficient management of battery temperature and overall vehicle performance.

Electronics Industry: Efficient Heat Dissipation and Non-Magnetic Properties

The electronics industry benefits greatly from the exceptional thermal conductivity of aluminum. Extruded aluminum shapes are widely used in electronic devices, such as computer cooling systems, radiators, and air conditioners. The efficient heat dissipation properties of aluminum help prevent overheating and ensure the optimal performance of electronic components.

The electronics industry benefits greatly from the exceptional thermal conductivity of aluminum. Extruded aluminum shapes are widely used in electronic devices, such as computer cooling systems, radiators, and air conditioners. The efficient heat dissipation properties of aluminum help prevent overheating and ensure the optimal performance of electronic components.

Furthermore, aluminum’s non-magnetic properties make it an ideal choice for applications involving magnetic fields or sensitive magnetic devices. Aluminum extrusions are commonly used to house wires, cables, and high-voltage transmission lines due to their non-magnetic characteristics. This ensures the integrity and reliability of electronic systems.

Conclusion: Unleashing the Potential of Extruded Aluminum Shapes

Extruded aluminum shapes have revolutionized various industries, providing unmatched strength, versatility, and cost-effectiveness. From construction and aerospace to automotive and electronics, the applications of extruded aluminum shapes are vast and diverse.

At American Douglas Metals, we are committed to delivering top-quality extruded aluminum shapes tailored to the unique requirements of each industry. Our precision drilling, countersinking, milling, tapping, and deburring services ensure that our extrusions meet the highest standards of precision and functionality.

With over four decades of experience and a strong commitment to customer satisfaction, we have become a trusted partner for numerous satisfied customers. Contact us today to explore the endless possibilities that extruded aluminum shapes offer for your industry.