Key Considerations In Selecting An Aluminum Extrusions Profiles Provider

Within the industrial sector, the utilization of high-quality manufactured materials is a fundamental prerequisite for ensuring the longevity, functionality, and overall performance of manufactured goods. Among these manufactured materials, aluminum extrusion profiles stand as a vital component, finding robust applications across a myriad of industries—ranging from automotive and construction to electronics and aerospace.

The attributes of aluminum—its malleability, strength-to-weight ratio, and corrosion resistance—coupled with the versatility of extrusion profiles, facilitate a multitude of design and engineering solutions. As industries progressively evolve, the demand for reputable and reliable aluminum extrusion profile providers surges correspondingly. This narrative delves into the critical considerations indispensable for selecting a proficient aluminum extrusion profiles provider, aiming to equip businesses with the information necessary to create advantageous partnerships and attain a competitive edge in their respective industries.

Understanding Aluminum Extrusions Profiles

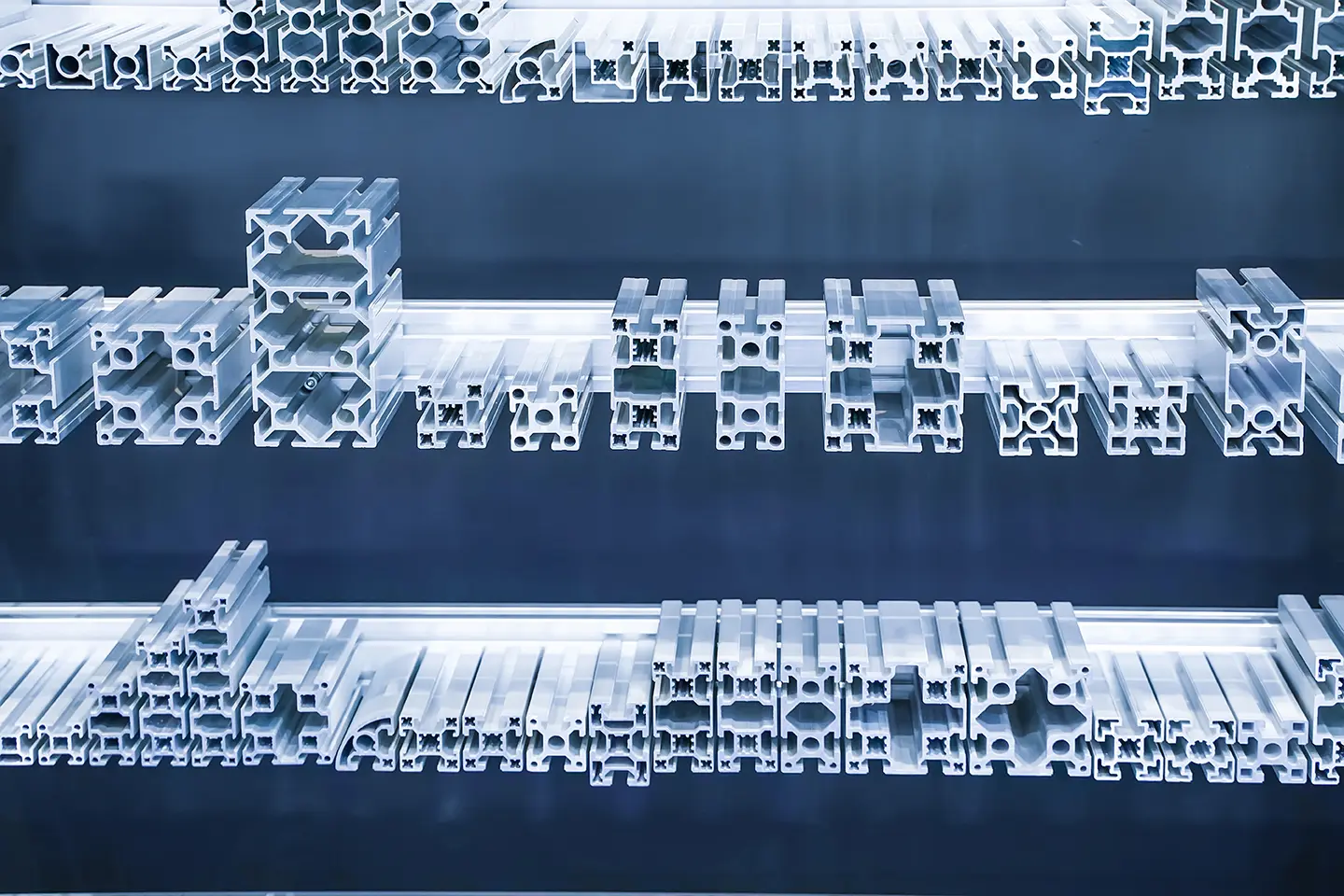

Aluminum extrusion profiles are long, continuous shapes created by pushing or pulling aluminum through a die, a shaped opening that imparts the desired profile to the aluminum. This process, known as extrusion, capitalizes on aluminum’s malleability to create an array of profiles suited to various applications.

Different Types of Aluminum Extrusions Profiles

Aluminum extrusion profiles come in several types, each suited to specific applications. Some of these types include:

Standard Profiles – These are the most common types, with a wide array of shapes and sizes. They are typically used in window and door frames, structural framing, and curtain walls.

Standard Profiles – These are the most common types, with a wide array of shapes and sizes. They are typically used in window and door frames, structural framing, and curtain walls.- Heat Sink Profiles – These are used in electronic devices, such as computer processors and LED lights. They feature fins or grooves that increase their surface area, allowing for efficient heat dissipation.

- T-Slot Profiles – Primarily used in industrial applications, such as machine guarding and structural framing, these profiles feature a T-shaped slot that allows for the attachment of various components.

- Conveyor Profiles – These are designed for use in conveyor systems, providing a lightweight and durable solution for material handling applications.

- Solar Panel Mounting Profiles – These profiles are specifically designed for mounting solar panels, offering a lightweight and corrosion-resistant alternative to traditional steel mounting systems.

Key Considerations for Selecting an Aluminum Extrusions Profiles Provider

When selecting an aluminum extrusion profile provider, there are numerous factors to consider. Here are some key considerations:

1. Quality of Products

1. Quality of Products

Regardless of the supplier’s other attributes, the quality of their products should be paramount. The provider should adhere to strict quality control standards and hold relevant certifications. This ensures that the extrusions you receive are of the highest quality and have passed rigorous testing procedures.

2. Supplier’s Experience

Experience speaks volumes about the supplier’s proficiency, operational efficiency, and knowledge of the market. An experienced supplier will understand your needs better, provide guidance on the right type of extrusion, offer custom designs, and suggest the most effective manufacturing process.

3. Production Capacity

It’s crucial to consider the supplier’s production capacity. They should have sufficient capacity to meet your demand, whether you need high or low-volume orders. A good supplier is reliable in meeting delivery schedules and has robust inventory management.

4. Customer Service

A good supplier values their customers and provides superior customer service. They should be responsive and transparent in their communication, guiding you through the process, and promptly addressing your questions.

5. Cost

Cost-effectiveness is vital for any business. You need to compare the prices of various suppliers and evaluate them based on your needs. However, be sure to focus on the total cost of ownership, don’t compromise on quality for the sake of a lower component price.

6. Location of the Supplier

The supplier’s location can impact shipping costs and delivery time. A supplier in the same region or time zone can save valuable time and ensure smoother business processes.

7. Additional Services

Suppliers offering additional services such as customization, after-sale services, or anodizing can provide added value to your business.

8. Supplier’s Track Record

A supplier’s past performance can provide essential insights into the reliability and quality of products. Look for reviews and ask for references to learn more about their track record.

Why Choose American Douglas Metals (ADM) as Your Supplier?

With over 43 years of experience in the industry, American Douglas Metals (ADM) is a trusted leader in the metals industry. We offer a wide range of aluminum extrusion profiles, catering to diverse industry needs. Our commitment to quality, innovation, and customer satisfaction sets us apart.

ADM is a family-operated enterprise with a vast presence across over 11 cities on the East Coast and Canada, overseeing sales offices, metal processing facilities, and warehousing centers. Our expansive experience is mirrored by the satisfaction of over 1000 customers.

We offer high-quality, high-strength metal materials, where experience meets excellence. Our team is dedicated to providing you with the best service, ensuring your business needs are met with precision and efficiency. Contact us to explore our range of aluminum extrusions profiles, and let’s build a strong partnership that benefits your business in the long term.