It’s Needed for Both Function & Form

It’s Needed for Both Function & Form

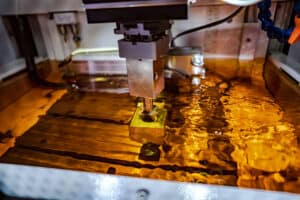

It doesn’t matter if we’re talking about factory floor machinery or the trim of a building; keeping your metals clean is a necessary maintenance, though for different reasons. Machinery must be kept rust-free to continue functioning at peak efficiency, and cosmetics simply need to look clean.

Whether you’re dealing with flat-rolled steel or aluminum extrusions, rust is something you need to keep an eye out for. Different metals have different susceptibilities to rust, but there are preventative means you can take to keep your metals from rusting and retaining that clean sheen. Industries like maritime, transit, and manufacturing must pay particularly close attention to rust degradation, as negligence will result in more frequent downtime and lost profits.

As premiere metal distributors in the U.S. for over 40 years, we know a thing or two about rust prevention. In this article, we’ll explain how susceptible different metals are to rusting and what you can do to extend the life of your metal before treating or replacing it.

Which Metals Are Resistant to Rust?

Steel

Rust is an iron oxide; it’s what you get by combining iron and oxygen. Because steel is a mixture of iron and carbon, it’s at risk of rusting. Despite being an incredibly tough material, steel is particularly susceptible to saltwater or acidic environments and must receive some sort of treatment on a regular basis.

Rust is an iron oxide; it’s what you get by combining iron and oxygen. Because steel is a mixture of iron and carbon, it’s at risk of rusting. Despite being an incredibly tough material, steel is particularly susceptible to saltwater or acidic environments and must receive some sort of treatment on a regular basis.

The kind of steel you purchase does affect this susceptibility, however. For example, stainless steel also has chromium in it, which has a natural resistance to rust. The presence of chromium won’t make your steel utterly immune, but it will increase your metal’s resistance to rusting in general.

Aluminum

Aluminum is naturally rust-resistant, in a sense. It forms a layer of aluminum oxide just like steel develops a layer of iron oxide, but it’s the nature of this layer that gives aluminum such a positive reputation.

When steel rusts, it flakes off, allowing the layer beneath to rust until the entire metal is gone. Aluminum oxide actually hardens, preventing oxygen and moisture from corroding the rest of the metal. However, it’s important to keep in mind that if you need your aluminum to appear perfect for cosmetic reasons, you’ll still need to treat it to stop that layer of aluminum oxide from developing.

Copper

Copper is all but impervious to rusting due to the fact that it has very little iron in it. It’s this resistance that classifies copper as a “noble metal.” However, just because copper won’t rust doesn’t mean it cannot corrode or oxidize, which kind of feels like false advertising for the metal itself.

Rather than developing a layer of flaky brown layer like steel or a hardened layer like aluminum, copper develops a green patina. This patina is caused by exposure to moisture and oxygen, much in the same way steel and aluminum develop rust. Though visually different, the effect is essentially the same and can lead to failure in copper parts if not treated or replaced.

A famous example of this patina effect is the exterior of the Statue of Liberty, which was created with copper. When the French first shipped it, the statue was brown, and over time the ocean air has corroded it into the green we know today.

Ways to Prevent Rust

Layer of Paint or Powder Coating

Layer of Paint or Powder Coating

The way you protect your metals is to mimic the effects of aluminum’s oxidation. To put that simply, all you need to do is cover your metal in a protective layer to stop oxygen and moisture from degrading the metal beneath.

Your first option (and a production service ADM provides) is to paint your metals. A layer of paint or powder coating will enhance the corrosion resistance of your metals and allow you to customize their appearance to your liking.

Anodize Your Aluminum

Anodizing aluminum is another production service we provide at ADM. We submerge your aluminum into an electrolytic bath, creating a layer of aluminum oxide that protects the metal from rusting, but without creating the marks that natural aluminum oxide will leave.

You’ll still need to periodically clean or treat your aluminum, but anodizing will go a long way to preventing rust. Steel and copper can technically be anodized, but not in the conventional sense, and they’re not services we provide at ADM.

Keep it Clean

If you’re presenting a show car or some other cosmetic surface, keep it clean! Debris and dirt will trap moisture and hasten the corrosion process. White vinegar will work on steel and aluminum, but Don’t use it on stainless steel; it will corrode. For stainless steel products, simple water and soap will do. Alternatively, you can utilize metal cleaners designed specifically to clean your particular metal.

Store it in a Dry Place

If your metal isn’t on display 24/7 like a building fixture, keeping it safe from the elements in a dry room is a great way to hold rusting at bay. That also means keeping humidity out of the air. So, if you’re located in a moist place like Florida, you’ll need to dehumidify the room or find another way to keep it dry to prevent corrosion from taking place.

Apply Oil or a Dry Coat

Semi-regularly applying oil to your metal is another great way to increase rust resistance. Alternatively, if your metal is going to be handled, a slippery surface might not be the best solution. In that case, you’ll want to use a dry coat to apply a similar layer of protection without creating a greasy surface.

Choose ADM for all Your Metal Distribution Needs

Applying any of these options or a combination will keep your metals looking as good as the day you received them and help to retain your machinery’s efficiency. We at ADM have provided metal distribution services for over 40 years, creating aluminum extrusions and flat-rolled steel, as well as several metal processing services.

Applying any of these options or a combination will keep your metals looking as good as the day you received them and help to retain your machinery’s efficiency. We at ADM have provided metal distribution services for over 40 years, creating aluminum extrusions and flat-rolled steel, as well as several metal processing services.

Want to know more about the processing and metal work we can do for you? Feel free to contact us.