Why Aluminum?

Aluminum extrusion is a widely used manufacturing process, but why should you choose aluminum over other, stronger materials like steel? Aluminum has many qualities that set it apart from other metals, like its innate corrosion resistance and its lightweight properties.

We’ll explain what sets aluminum apart from other materials, including its characteristics and the roles it currently fills in different industries.

The Many Strengths of Aluminum Extrusion Profiles

Versatility

Versatility

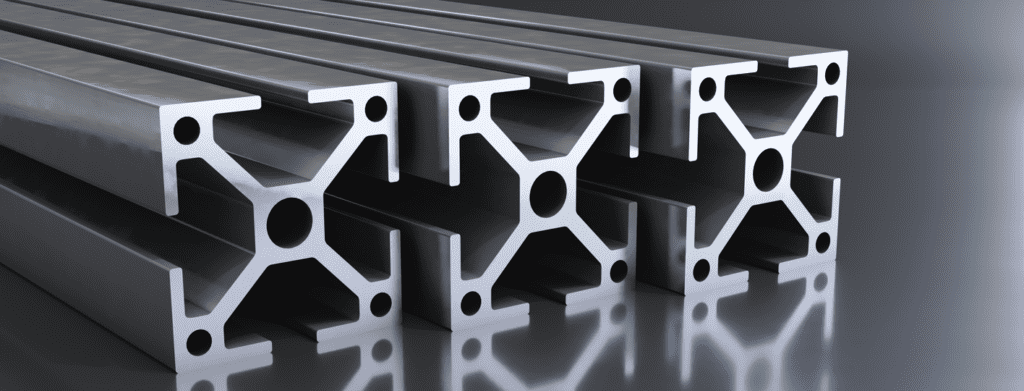

One of the most significant advantages of aluminum extrusion profiles is the material’s versatility. Compared to other metals like steel, aluminum is easier to mold into unique shapes. Aluminum has a lower melting point compared to many other metals, so it requires less energy to heat it for the extrusion process.

Despite this lower melting point, aluminum can be given additives to make it stronger than many variants of steel. The material is perfectly suited for certain load-bearing roles, as well as decorative ones. However, it should be noted that steel is still superior for extreme load-bearing roles, like support beams in construction.

Aluminum extrusion profiles can be customized to meet a client’s specific design requirements and offer numerous possibilities for engineers and designers.

Lightweight & Strength-to-Weight Ratio

Aluminum is much lighter than other metals, making it easier to handle, transport, and install. Depending on the size of your aluminum extrusion profile order, this could drastically reduce the cost of shipping the material to your worksite.

Aluminum’s also an ideal material for manufacturers looking to reduce the weight of their products, like the automotive industry. Aluminum has an excellent strength-to-weight ratio, providing the necessary structural strength without adding unnecessary weight.

Corrosion Resistance

Corrosion Resistance

When most metals rust, they need to be cleaned off and treated to stop the process from degrading the material further. Aluminum isn’t the same. It rusts just like other metals, but that rust forms a protective layer that shields the rest of the aluminum extrusion profile from further degradation. If the aluminun isn’t intended to be a display piece, you’ll save on costly water-resistant treatments.

This characteristic makes custom aluminum extrusions suitable for use in harsh environments and applications where corrosion resistance is crucial, such as marine structures, outdoor installations, and chemical processing facilities.

Thermal and Electrical Conductivity

Aluminum is an excellent conductor of both heat and electricity, making it ideal for applications requiring thermal management or electrical grounding. Custom aluminum extrusions are often used in heat sinks, radiators, and electrical enclosures, where efficient heat dissipation and conductivity are essential.

Recyclability and Environmental Impact

Recyclability and Environmental Impact

Finding an eco-friendly material is difficult. Many aren’t recyclable, and those that are tend to weaken each time they’re put through the process. Aluminum is a different story. It can be recycled repeatedly without losing its properties, making it one of the most environmentally friendly material choices in the world. The recycling process for aluminum also requires significantly less energy than producing new aluminum, reducing its overall environmental impact.

Surface Finish and Aesthetics

Aluminum extrusion profiles can be easily anodized, painted, or powder-coated to improve their appearance and durability. This allows for a wide range of color and finish options to suit specific aesthetic requirements. These surface treatments can also enhance the corrosion resistance and wear resistance of aluminum extrusions.

Cost-Effectiveness

As of the writing of this article, aluminum is one of the more expensive raw metals on the market, but there are other overhead costs that aren’t immediately apparent.

- Aluminum is lightweight – This was mentioned earlier. Aluminum is a light metal, meaning shipping costs will be far lower compared to heavier materials like steel.

- Easier to process – Because of aluminum’s lower melting point, it’s easier to shape and requires less energy to heat for the extrusion process. That combined with the lower tooling and manufacturing costs makes the entire building process less expensive.

- Secondary treatments – If the end product isn’t meant to be decorative, you can avoid paying for the anodizing treatment to make it water resistant, reducing the final cost of the components.

The flat cost of aluminum may be higher than alternatives like steel, but these ancillary costs have a way of sneaking up on the balance sheet.

What Are Aluminum Extrusion Profiles Typically Used For?

Aluminum extrusion profiles don’t have the strength of higher grades of steel, but sheer strength isn’t always the answer. Aluminum has a great many uses, and the following only scratch the surface:

Aluminum extrusion profiles don’t have the strength of higher grades of steel, but sheer strength isn’t always the answer. Aluminum has a great many uses, and the following only scratch the surface:

Automotive industry – Aluminum’s lightweight characteristic makes it an ideal material for lowering the total weight of cars and trucks, thereby reducing customers’ gasoline consumption.

Construction – Aluminum is more visually appealing than many other metals. With the right treatments, it can be used for rims, facades, paneling, and other decorative roles in construction projects.

Thermal equipment – Aluminum’s thermal and electrical conductivity makes it a commonly-found material in heat sinks, air conditioners, and radiators.

Ocean-side equipment – Ocean air is exceptionally damaging to most metals, but aluminum’s innate corrosion resistance makes it perfect for panels, supports, railings, or any other metallic component on docks by the ocean.

Automation lines – Aluminum extrusions are also commonly found in automated manufacturing lines across several manufacturing industries.

For Reliable Metal Processing, Look no Further Than American Douglas Metals

Aluminum extrusion profiles have many innate qualities that make them the superior choice to alternative metals. However, none of those advantages mean anything if you receive crates of poorly-processed materials.

Problems like incorrect measurements or poorly done protective coatings can put a project back months. With modern-day deadlines being as strict as they are, that’s not an option.

American Douglas Metals has been processing metals for over 40 years. Our team of machinists are industry veterans and can cut, shear, and create custom aluminum extrusions to your exacting specifications.

For more information on how American Douglas Metals can serve your needs, contact us today!