CARBON STEEL COILS

DEPENDABLE, PREMIUM ALLOYS

American Douglas Metals (ADM) supplies high-strength, flat-rolled carbon steel coils for a variety of industrial and manufacturing applications. Our large product inventory can be custom-formatted and sized for your exact project specifications.

Our carbon steel coils are available in the following formats and finishes:

Cold-Rolled

Cold Rolled products are processed similarly to hot-rolled but include an added step to achieve a more exact dimension on the steel finish. After the steel has cooled down, it is run through the rolling mill once again to modify the surface area. Cold rolling creates a product that works best for projects that require smooth services, well-defined edges, and corners such as domestic appliances. The only downside to cold-rolled metals is that it requires more pressure compared to hot rolling because the cooled steel is not as malleable.

Galvanized

This steel finish involves adding a coating of zinc to the steel to offer an added protection and prevent rusting. Galvanized steel is one of the more popular finished products due to its extended durability. The zinc protects the base metal by acting as a barrier creating a long-lasting and high-quality steel product.

REQUEST QUOTES OR

ADDITIONAL INFORMATION

To speak with an American Douglas Metals (ADM) representative regarding our available products or services, please fill out the form below and we will contact you as soon as possible.

Galvannealed

Galvannealed finish is created through the combination of the annealing process and hot-dip galvanizing to create its final coasting. The steel is coated in the hot-dip zinc and then headed to induce alloying between the zinc coating and the steel. The finish replicated a dull matte surface that allows for paint adhesion and welding as needed.

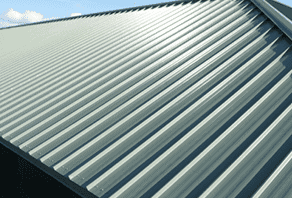

Galvalume

Galvalume consists of a special coating comprised of zinc, aluminum, and silicon to protect the steel from oxidation. It has an advantage over other galvanized materials due to its enhanced protection from rust when exposed to water and other liquids. This hot-rolled steel works well for outdoor environments such as it can hold its own against snow, ice, and rain.

Acrylume

Acrylume offers more protection to galvalume steel products. Acrylume is a clear, organic resin that is roll coated onto the metal surface and creates a layer of acrylic to create corrosion resistance.

Hot-Rolled Pickled and Oiled

Steel pickling and oiling is a type of metal surface treatment finish to remove surface impurities like rust and carbon scale from a hot-rolled steel product. The steel is dipped into a bath of pickle liquor which consists of hydrogen chloride acid solution. The oiling process is similar but the solution the material is dipped into consists of a water-soluble or a mineral-based oil to help prevent flash rust while the material waits for further fabrication.

Master Coils

This wide roll of coiled steel will be used to be slit into multiple narrower coils. For many industries, the use of one large master coil can be endless as they can further fabricate it in-house at their own facility.

Slit Coils

If a master coil is in need to be slit into narrower coils, our metal services equipment has the ability to create the slit coils needed to complete any project needs. Dependent on the needs of the client and their specifications, we have the ability to slit our carbon steel coils into a narrower coil. Various industries need specific measurements in order to complete project goals. We have a designated team of professionals ready to punch in specifications into our machines and check for quality assurance throughout the fabrication process.

Mill Finish

Mill Finish is the natural appearance of the aluminum material as it comes from the rolling mill or the extrusion mill. It is “as is” with no external mechanical or chemical finishing. Extruded metal is considered a “mill finish”. All aluminum has an oxide of varying thickness.

Painted

Painted finishes offer extreme durability in outdoor exposure as well as indoors because of our high-quality paint system. Pre-painted aluminum sheet finishes are uniquely designed in that they provide a hard, abrasive resistant coating, yet allow the flexibility for extensive forming and fabricating on a metal surface.

Embossed

Embossing is a marking process that leaves raised designs on metal and other materials. The process utilizing rollers or dies combined with pressure to mark the metal sheets with a series of designs. This technique is great for creating slip-resistant platforms, stairs, and a range of other custom-designed steel and metal products.

As your preferred carbon steel coils supplier, ADM can stock, process, warehouse, and ship direct the available material to your location from one of our multiple facilities.

YOUR TRUSTED MATERIAL PROVIDER

With over 43 years of experience in the industry, ADM has evolved from a small distribution company based in Buffalo, NY to a third-generation, family-owned, and operated with offices, metal processing facilities, and metal warehousing center in more than 11 countries throughout the East Coast.

SLITTING

Precise cutting to create custom-width coils.

CUT-TO-LENGTH

Converting flat-rolled coils into custom sized sheets.

BLANKING

Producing smaller sheets via CTL and/or shearing.

EMBOSSING

Pattern pressing for aluminum and steel

coiled metals

SHEARING

Reworking larger sheets into smaller sheets.

CNC MACHINING CENTER

State of the art, custom aluminum extrusion fabrication facility.